Stage・System Design and Fabrication

Save Time and Man-hours with Custom Orders

Fusion of Ultra-Precision Positioning with the Highest Level of Planar Granite Surface Plate

Proposals from Technology Leaders with more than 50 years of Experience and Expertise

Do You Want to Save Time and Man-hours?

In many cases, Japanese machine and equipment manufacturers design precision positioning from scratch to procure and manufacture their own stages and actuators.

However, this requires a lot of time and man-hours. Precision positioning is a key part of processing, measurement and analysis, which can be done in collaboration with experts or with positioning products already unitized with high precision.

Precision Positioning Alone is Not Enough

The stage on which the workpiece is mounted moves at high speed and provides highly precise positioning, but its speed and precision are improving year by year, and demands are increasing.

Vibrations is unavoidable in high-speed operation or intense acceleration and deceleration, and even after a stop, a slight vibrations remains in the equipment for a while, which interferes with the precision and speed of processing and measurement.

To minimize these vibrations and shorten the convergence time, the device should be built on a hard, heavy base, especially one made from polished granite, which is ideal for minimizing vibrations.

We can produce granite stone surface plates with the highest level of flatness. These stone surface plates are used in applications requiring high precision in the fields of semiconductors, life sciences, photonics, and industrial automation.

With solutions that only PI Group can provide

We now become part of PI Japan Co., Ltd., a subsidiary of Physik Instrumente (PI) GmbH, a German capital and precision positioning manufacturer.

PI, headquartered in Karlsruhe, Germany, is a market and technology leader in precision positioning in high-tech business sectors such as life sciences, semiconductor manufacturing, photonics and industrial automation

Being a part of the PI Group with more than 50 years of experience and technology has made it possible to develop, design, manufacture, and install single-axis to multi-axis ultra-precision positioning systems, precision measurement equipment, and manufacturing equipment, as well as offer engineered system products that combine a highly stable granite base.

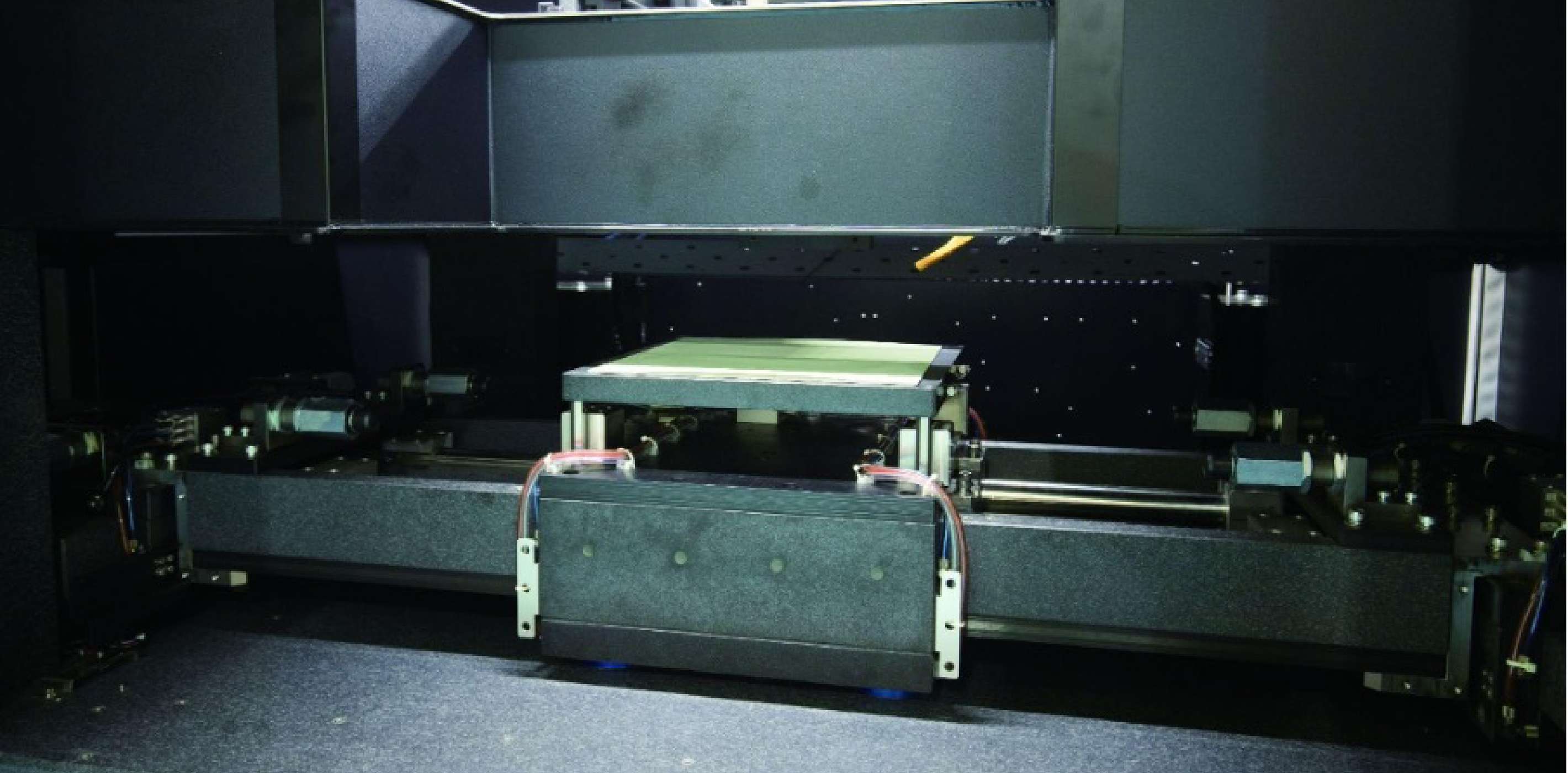

Precision Compact Air Slide XY Stage GRANAS-10XY-GL

Granas-10XY-GL Laser, Galvano and XY Ultra-Precision Compact Stage are synchronously linked.

- Features

-

- Applicable to various lasers

- Adoption of active vibration isolator and porous suction table

- Application

-

- Various lasers, Laser micro-machining (welding, cutting, scribing, drilling, etc.)

- Laser Markers

- Measurement Equipment

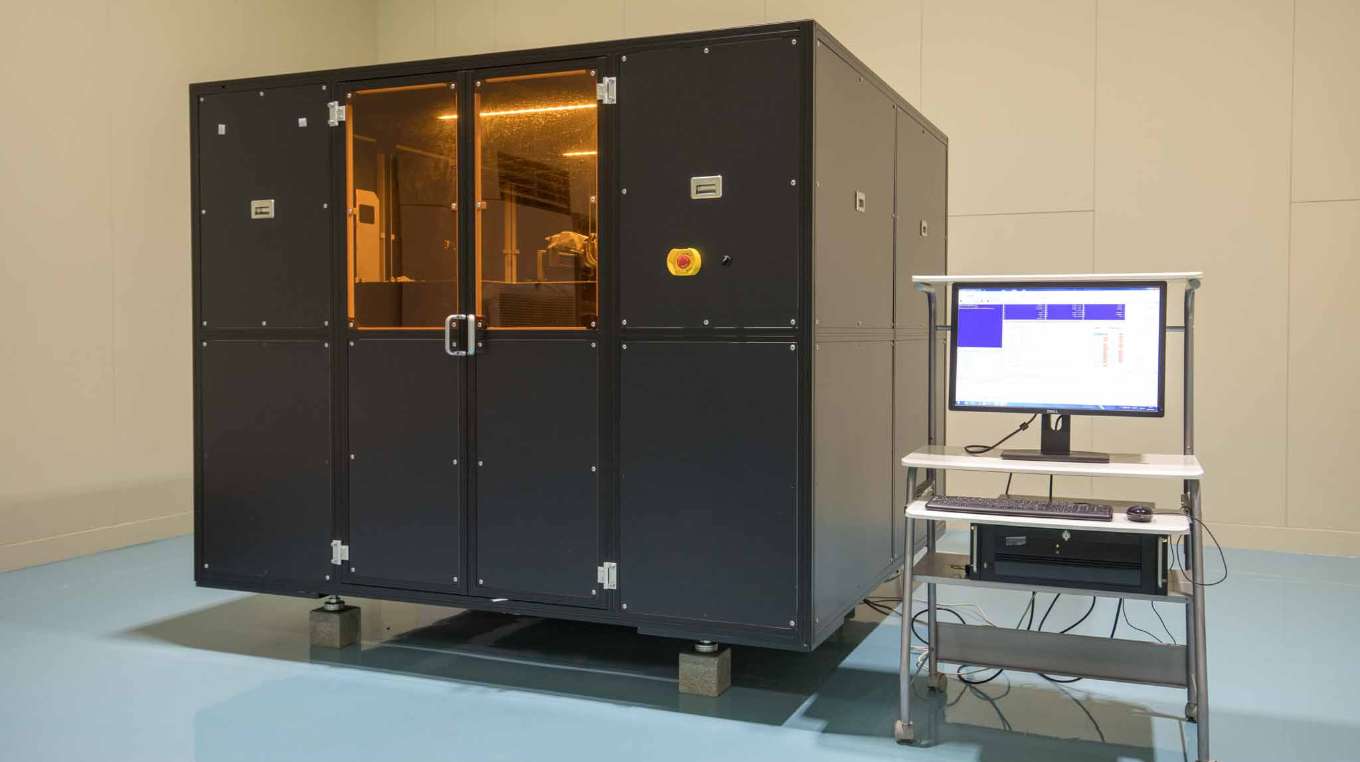

Galvano Interlocking Ultra-Precision Stage GRANAS-40XY-GL

This system synchronously links the laser, Galvano, and XY ultra-precision compact stage.

- Features

-

- Suitable for various lasers (532nm, pulsed laser, etc.)

- Equipped with Canon Galvano Scanner

- Equipped with XY Ultra-precision Granite Air Slider

- Equipped with Controller PowerPMAC

- Application

-

- Laser micro-machining (welding, cutting, scribing, drilling, etc.)

- Laser markers

- Measurement equipment

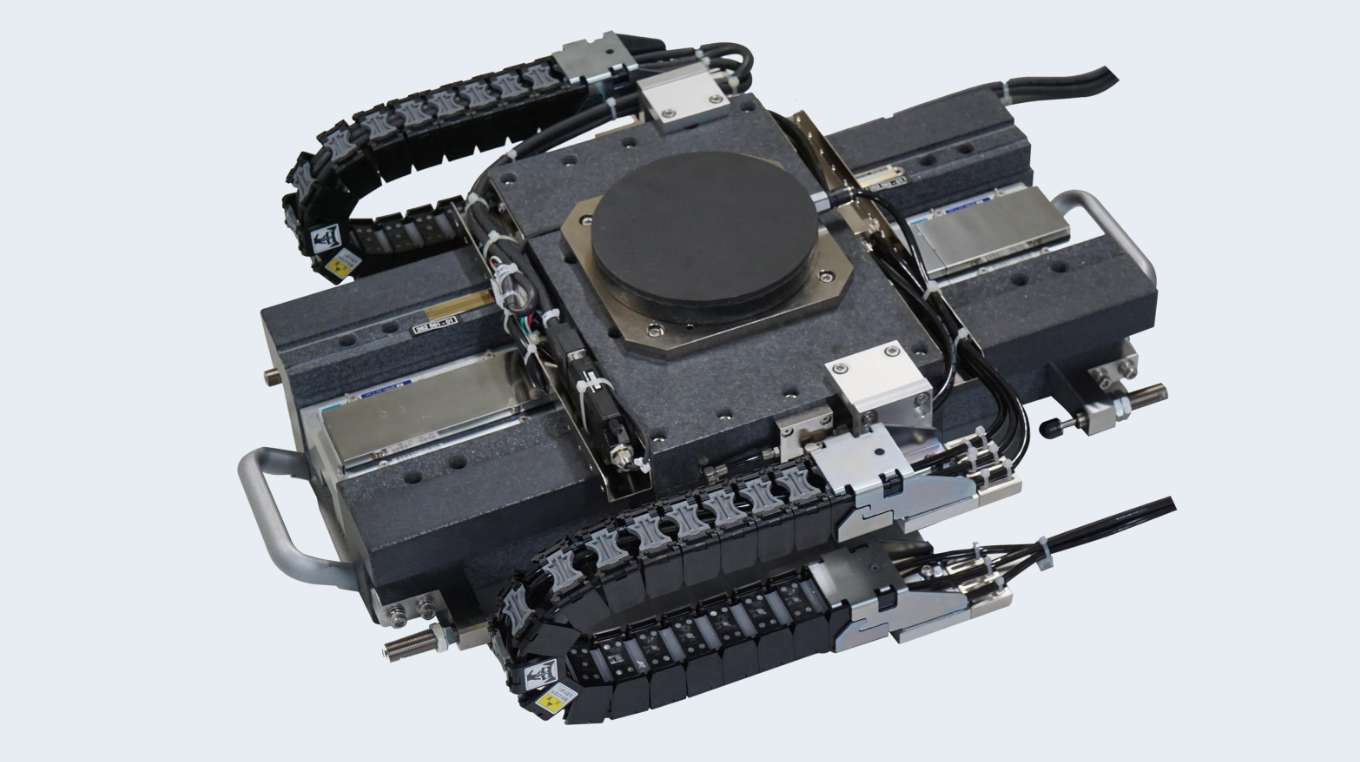

Precision Air Slider Single Axis Table GRANAS-30X

Perfect for Inspection and Processing Machines that Require High Accuracy Straightness, Constant Speed, and Positioning.

- Features

-

- It is an air slider with high precision and excellent cost performance using granite (porphyry rock) as the main materials.

- High positioning accuracy is possible with extremely small sliding resistance.

- Slider and drive part are completely non-contact (lubricant is not required), so it is clean and maintenance-free.

- They move contactlessly in track, providing high straightness accuracy.

- Application

-

- Semiconductor and liquid crystal aligner

- Semiconductor and liquid crystal inspection device

- High-precision shape inspection system

- Ultra-precision processing equipment, etc.

CAM Software for Laser Drawing

It is also possible to create a variety of software for system construction.

Customization to specifications is available.

Reduce time and man-hours with custom order for precision positioning

Accuracy of the highest level is achieved with precision positioning + granite surface plate.

Please feel free to contact us first