Stone Surface Plate

We offer a wide range of services from standard stone surface plates

to custom orders for precision positioning units.

About Stone Surface Plate

Features of Stone Surface Plate

Almost No Aging

Although the heat treatment technology of cast-iron surface plates has been improved, aging is unavoidable. On the other hand, granite used in stone surface plates is made of gabbro, natural stone with an excellent uniform structure, and has been naturally seasoning for thousands of years. Therefore, it shows almost no aging.

High Wear Resistance

Granite is more than twice as hard as cast-iron and has high wear resistance.

(Reference: Shore hardness)

Gabbro --- Hs73~93

Granite --- Hs70~80

Cast-iron --- Hs32~40

Excellent Corrosion Resistance

It has excellent corrosion resistance compared to cast-iron because it does not rust and loses less weight against acid.

No Burr Even with Scratches

If a scratch is made on the surface of a cast-iron surface plate, burrs or bulges occur due to the stickiness of the material and the flatness is impaired. If burs or bulges occur, the measurement accuracy will get worse and measurement objects and measuring instruments will be damaged. Granite stone surface plates have a hard, fine-grained structure, and are less sticky than cast-iron, so there are no burrs or bulges, and no deviation in flatness, so no damage is caused to measuring instruments.

Non‐magnetic Material

Granite is a non-magnetic material, so it can be used in magnetic equipment.

*Ferromagnetic materials may be affected.

Low Maintenance Costs

Granite does not rust, so it has a long life and low maintenance cost compared to cast-iron surface plates.

Vibration Isolation Performance (vibration isolation and vibration attenuation)

Stone surface plates have high stiffness and vibration attenuation, so they have excellent vibration isolation performance and are suitable for surface plate materials.

For example, a surface plate mounted on a vibration isolator not only places equipment on it, but also has a significant impact on the performance of the vibration isolator.

It is necessary to minimize the impact of many specific frequencies of the elastic structures of the equipment mounted on the surface plate on its intended use.

For this reason, it is necessary to increase the resonant frequency of the surface plate with its high stiffness, and reduce the resonance peak by increasing the vibration attenuation effect.

Therefore, stone surface plates take advantage of their characteristics and can be obtained by combining them with vibration isolators.

Stability and Temperature Change

Granite used in stone plates has a low thermal conductivity and hardly affected by temperature change, and has a high stability because seasonings are formed in nature.

Even in a room equipped with a device that maintains a constant temperature, it reacts insensitively to periodic temperature cycles, so it hardly deforms when the cycle is short.

Deformation due to temperature changes can be calculated and reproduced.

Used as a Base for Various Precision Instruments

Granite is suitable as a machine base due to its features, but it is also used as a base for precision instruments because special processing techniques such as screw bushing and drilling have been greatly improved.

Granite has a number of advantages, but the lack of stiffness, which is said to be a disadvantage, can be adequately compensated for by increasing the "thickness" of each dimension.

Inspecting Surface Plate

High quality products come from precise standards. It is a stone surface plate for inspection, measurement and assembly of components with long years of experience and know-how.

Even in a room equipped with a device that maintains a constant temperature, it reacts insensitively to periodic temperature cycles, so it hardly deforms when the cycle is short.

Deformation due to temperature changes can be calculated and reproduced.

Inspection Surface Plate Dimension and Accuracy Table (JIS B7513) General Example

| Dimension | Weight kg | Class 1 | Class 0 | Class 00 | Dimension | Weight kg | Class 1 | Class 0 | Class 00 |

|---|---|---|---|---|---|---|---|---|---|

| 300x300x75 | 20 | 8.0 | 4.0 | 2.0 | 750x750x125 | 204 | 12.0 | 6.0 | 3.0 |

| 300x450x75 | 29 | 9.0 | 4.5 | 2.0 | 1000x750x150 | 326 | 13.0 | 6.5 | 3.0 |

| 300x500x100 | 44 | 9.0 | 4.5 | 2.0 | 1000x1000x150 | 435 | 14.0 | 7.0 | 3.5 |

| 400x500x100 | 58 | 9.0 | 4.5 | 2.5 | 1500x1000x200 | 870 | 16.0 | 8.0 | 4.0 |

| 500x500x100 | 73 | 10.0 | 5.0 | 2.5 | 2000x1000x250 | 1,450 | 19.0 | 9.5 | 4.5 |

| 600x450x100 | 78 | 10.0 | 5.0 | 2.5 | 2000x1500x350 | 2,610 | 20.0 | 10.5 | 5.0 |

| 600x600x125 | 131 | 10.0 | 5.0 | 2.5 | 2000x2000x350 | 4,060 | 22.0 | 11.0 | 5.5 |

| 750x500x125 | 136 | 11.0 | 5.5 | 3.0 | 3000x1500x400 | 5,220 | 26.0 | 13.0 | 6.5 |

| 600x900x125 | 196 | 12.0 | 6.0 | 3.0 |

*Other sizes than the above are also available / Other sizes and dedicated frames are also available.

Frame Dimensions

| No. | Model Number | Stone Surface Plate Size | With/Without Casters | Frame Weight |

|---|---|---|---|---|

| 1 | P202101 | For 500x500x100 | Selectable | 37.5kg |

| 2 | P202102 | For 600x450x100 | Selectable | 38.5kg |

| 3 | P202103 | For 600x600x125 | Selectable | 52.6kg |

| 4 | P202104 | For 750x500x125 | Selectable | 52.4kg |

| 5 | P202105 | For 900x600x125 | Selectable | 56.9kg |

| 6 | P202107 | For 1000x750x150 | Selectable | 60.6kg |

| 7 | P202108 | For 1000x1000x150 | Selectable | 65.0kg |

| 8 | P202109 | For 1500x1000x200 | Selectable | 81.1kg |

| 9 | P202111 | For 2000x1000x250 | Selectable | 119.5kg |

*The sizes not listed are also available.

Measurement Equipment

Stone Master

Right-angled Square

Right-angled Square

Straight Edge

Straight Edge

Stone Cubic Master

Stone Cubic Master

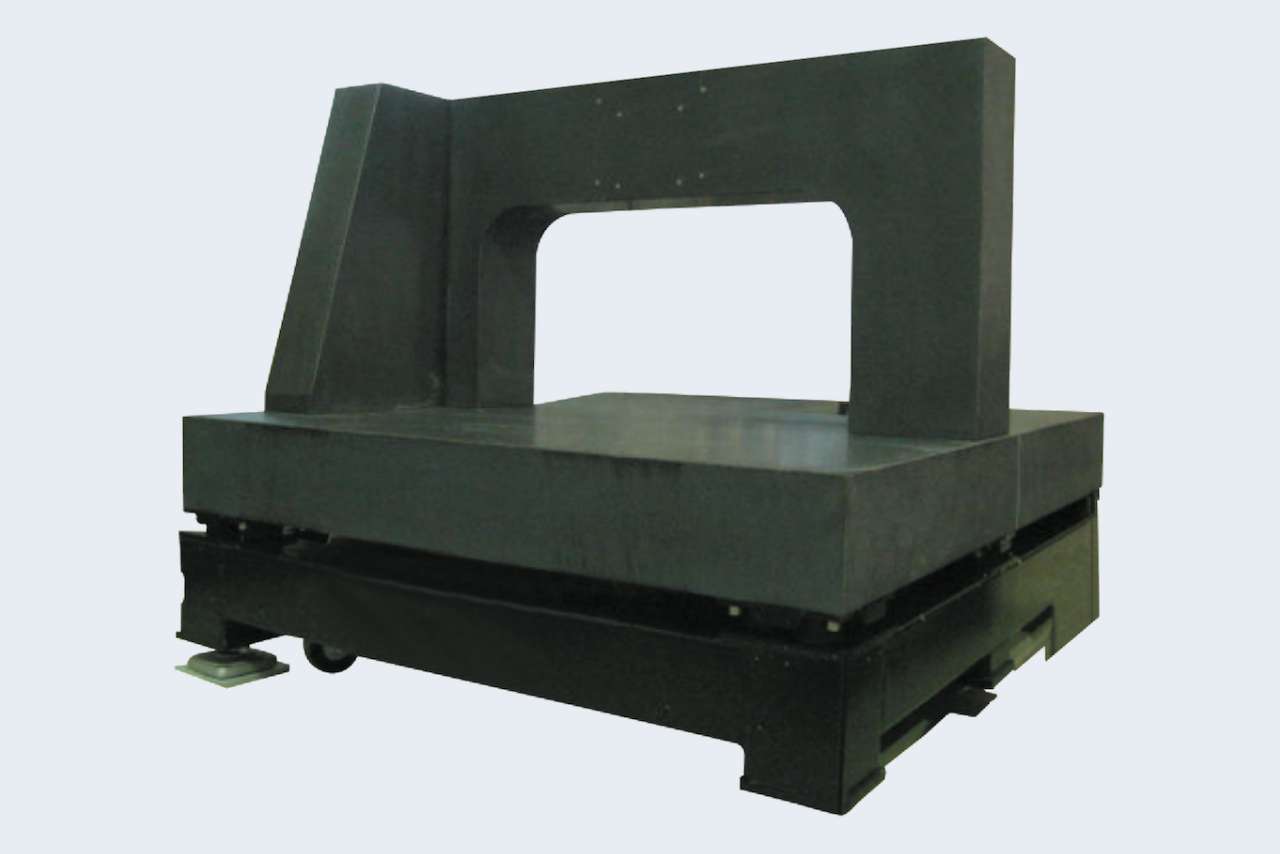

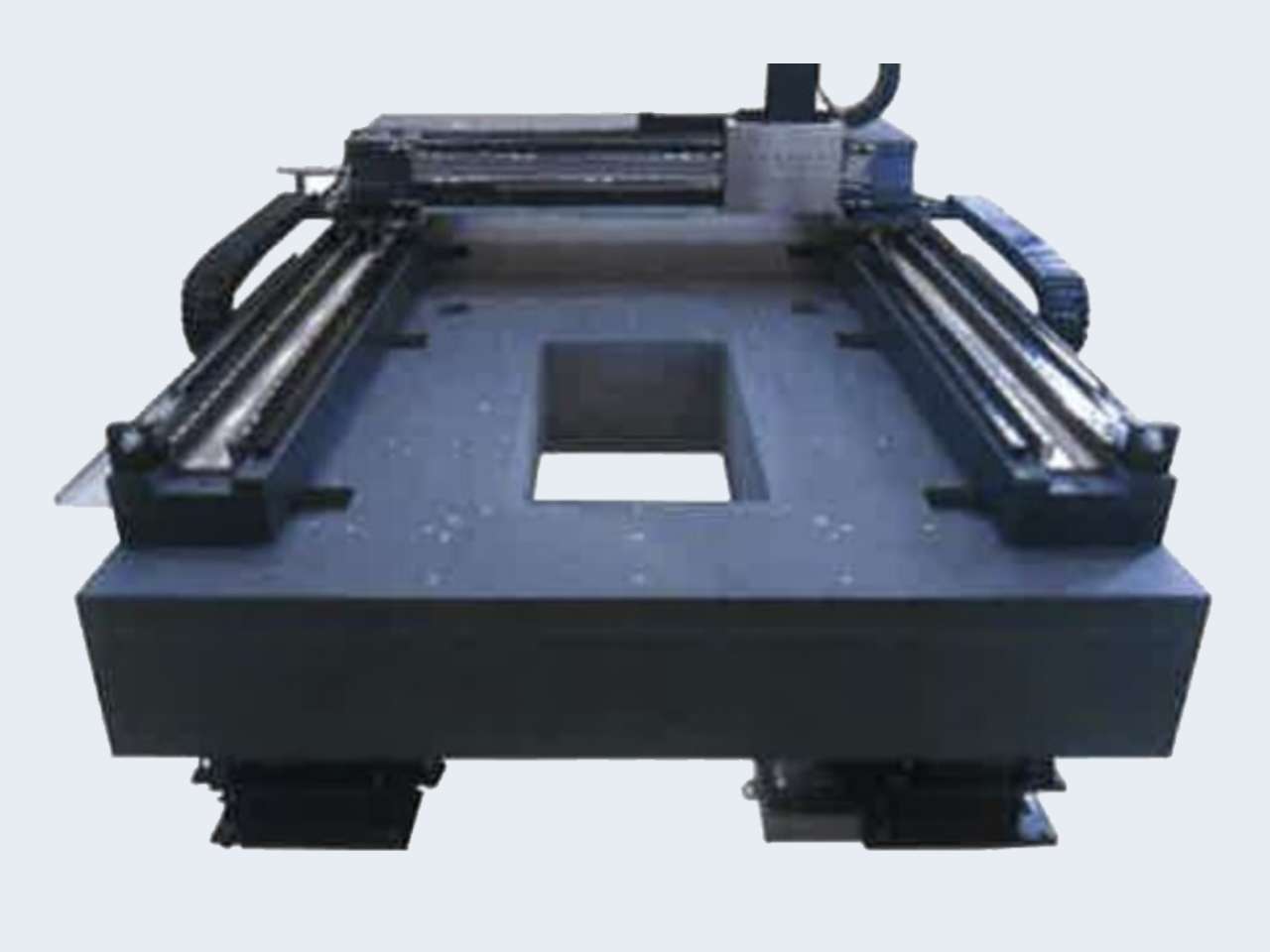

Machine Base

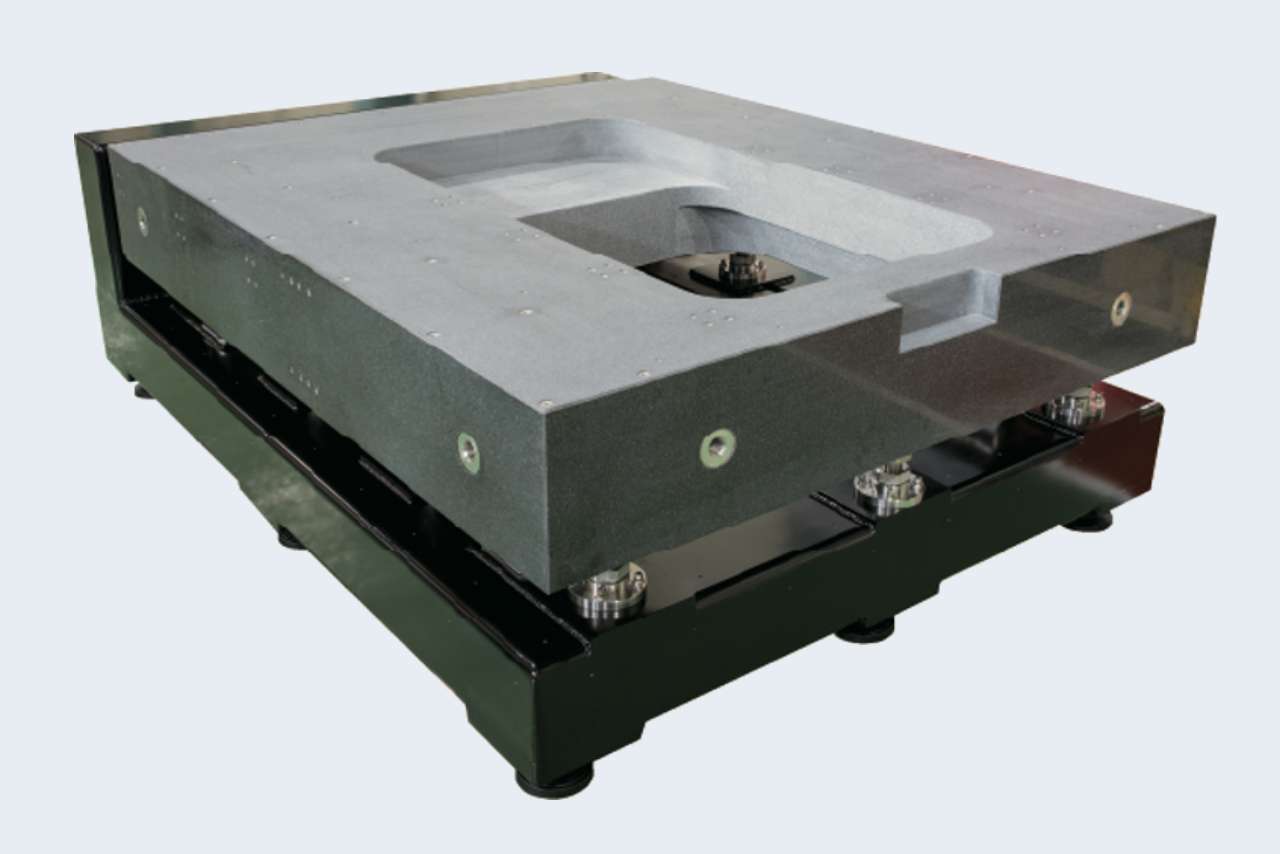

Can Frame + Machine Base

Accuracy is achieved by attaching a granite base to the frame.

Vibration Isolation Table + Machine Base

The stage and vibration isolation table are assembled to verify the accuracy of the seating and floating point.

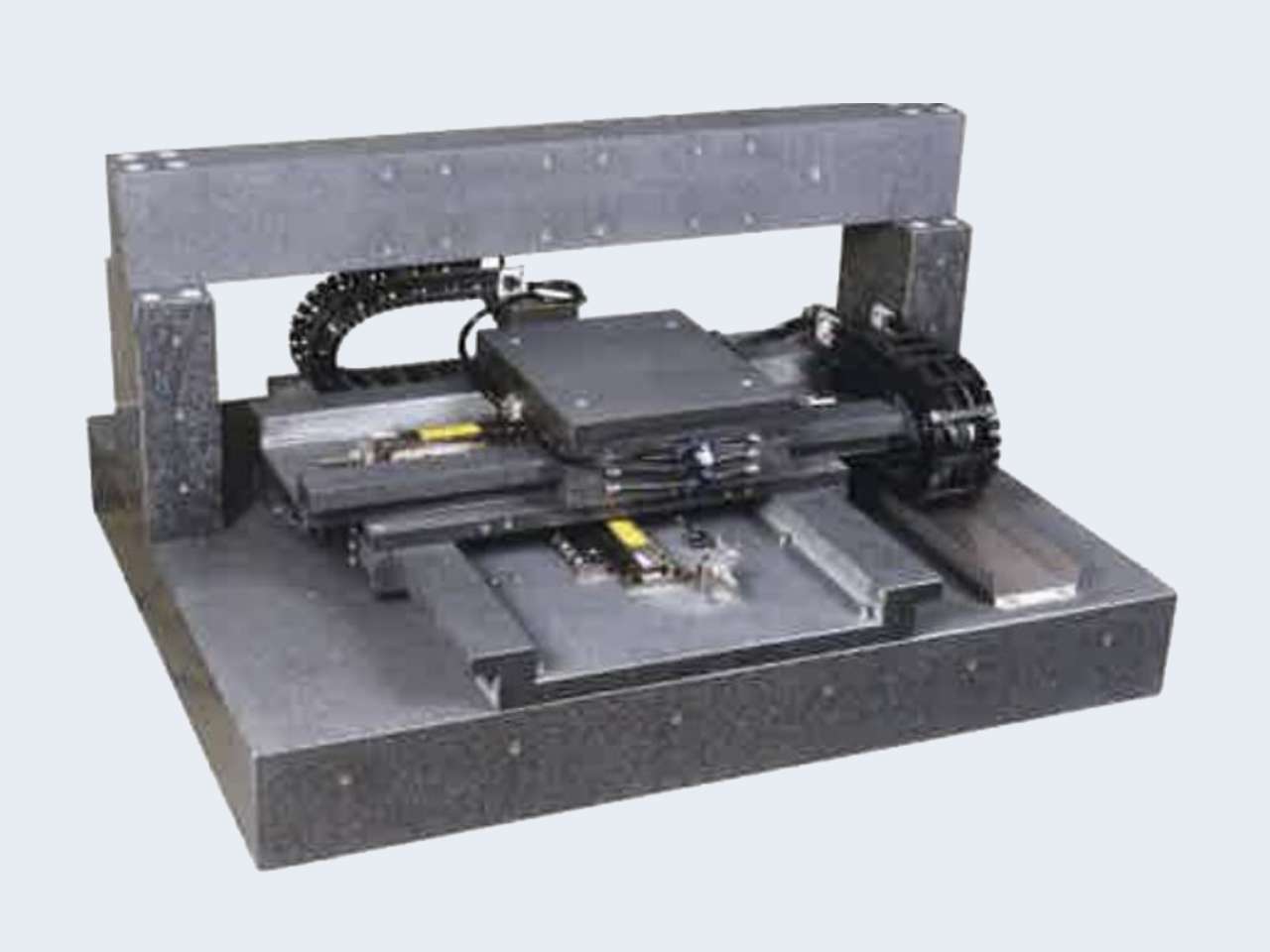

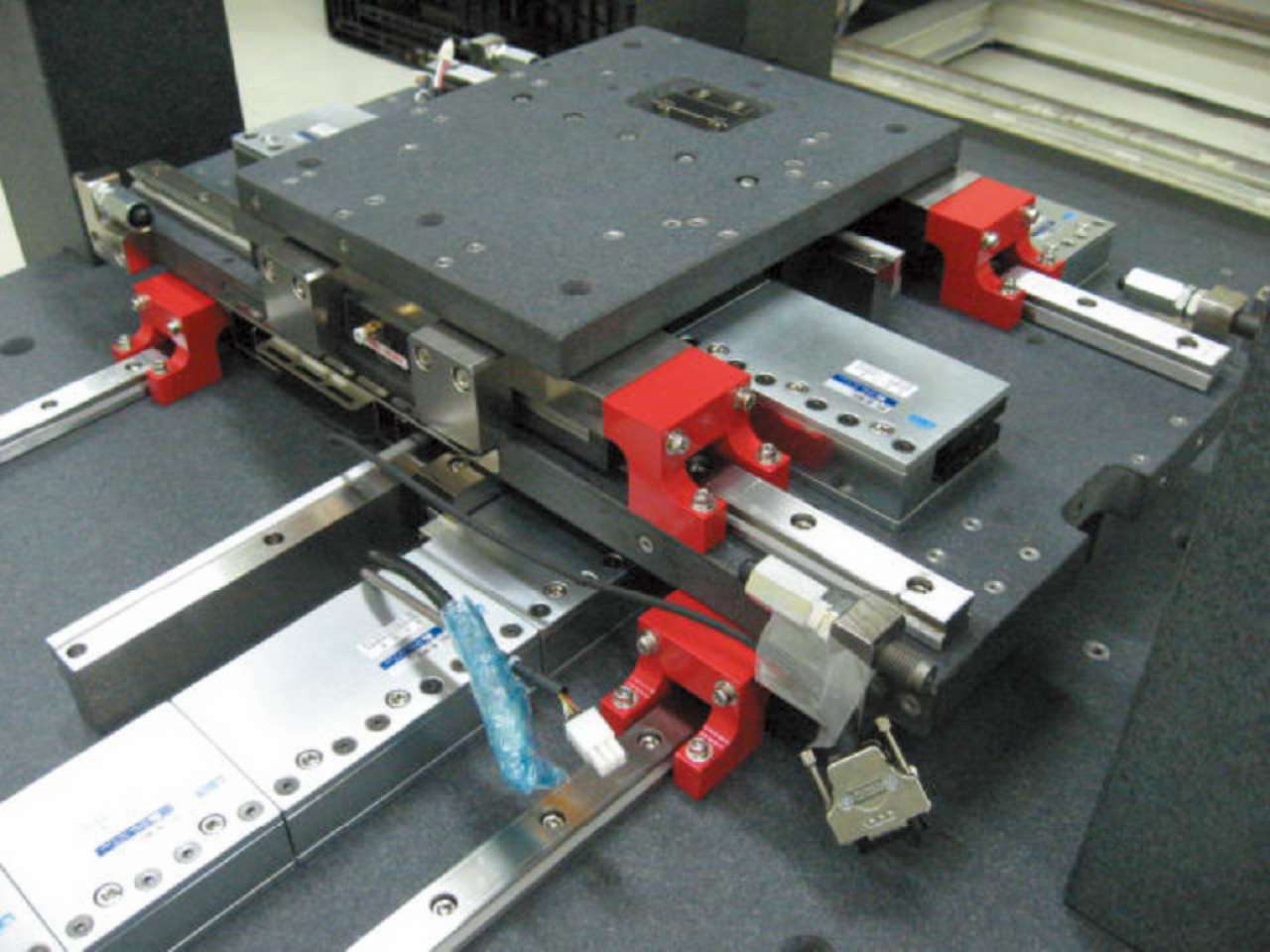

Precision Positioning Unit

XY Air Slider

XY slider with low center of gravity and high accuracy. Large sizes (1000 x 1000ST) can be accommodated, and short delivery times can be provided.

| Stroke | 450x450 ST |

|---|---|

| External Dimensions | 890x800x200 |

| Orthogonal Degree | 2μm |

| Straightness (Vertical) | X・Y Axis 0.5μm |

| Straightness (Horizontal) | X・Y Axis 0.5μm |

Uniaxial Slider

As the size of the equipment increases, the weight is reduced by the unique hollow structure to achieve the weight in the long stroke.

Maximum stroke is possible up to 5000 mm.

We will make it according to your desired shape, stroke and accuracy.

| Stroke | 3500 ST |

|---|---|

| Straightness (Vertical) | 0.5μm |

| Straightness (Horizontal) | 0.5μm |

LM Guide Assembly Adjustment

While assembling each part, the accuracy is adjusted to increase the flatness of the top table

We can attach scales and adjust the assembly of linear motors and other components.

| Stroke | 450x450 |

|---|---|

| Flatness | X・Y Axis 3μm |

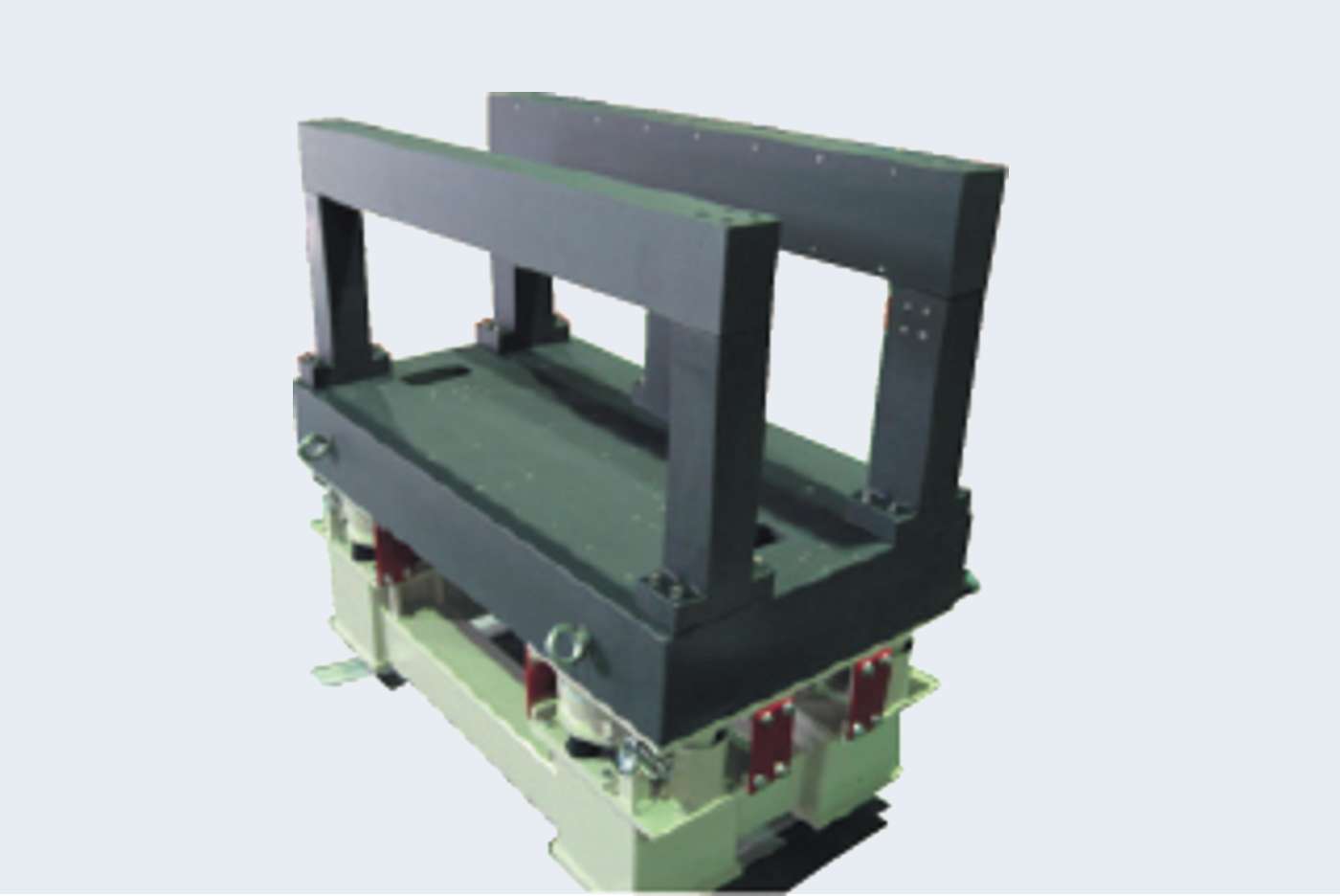

Assembly Machine Base

From large stages to small ones, columns, beams, rails, etc., are manufactured, assembled, and accuracy guaranteed with Granite.

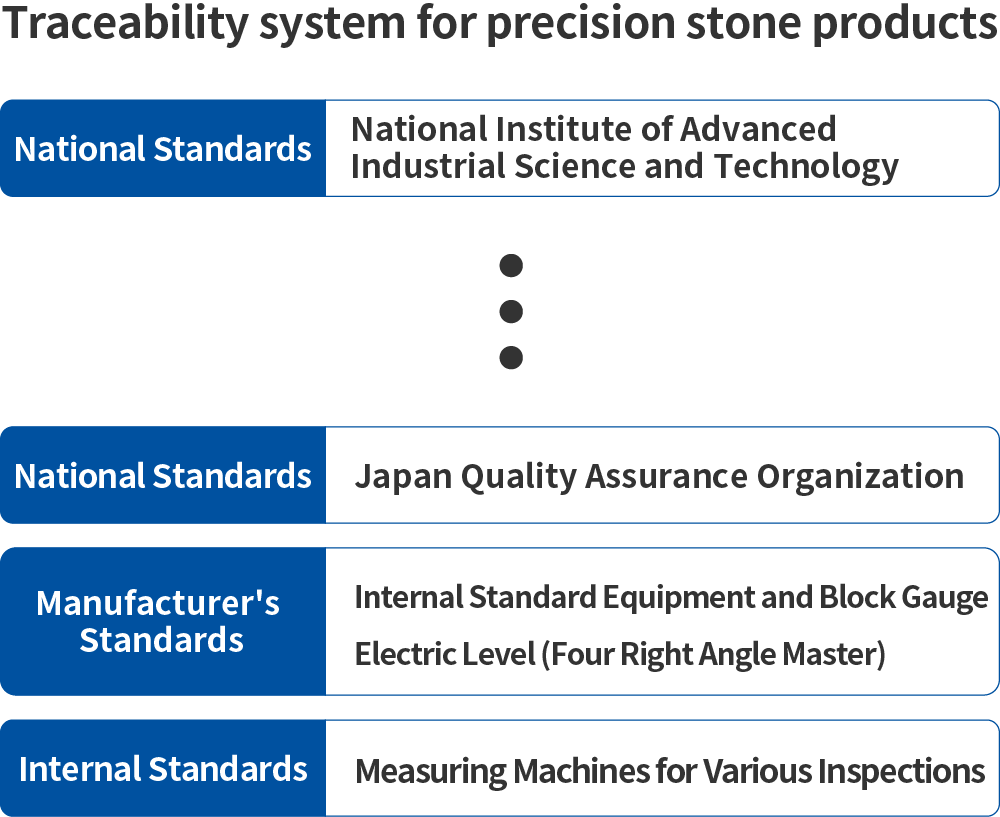

Maintenance, Repair and Calibration of Stone Surface Plate

To maintain the accuracy of stone surface plates, regular accuracy checks are necessary. We can also provide repairs, certification, and additional work together with regular inspection.

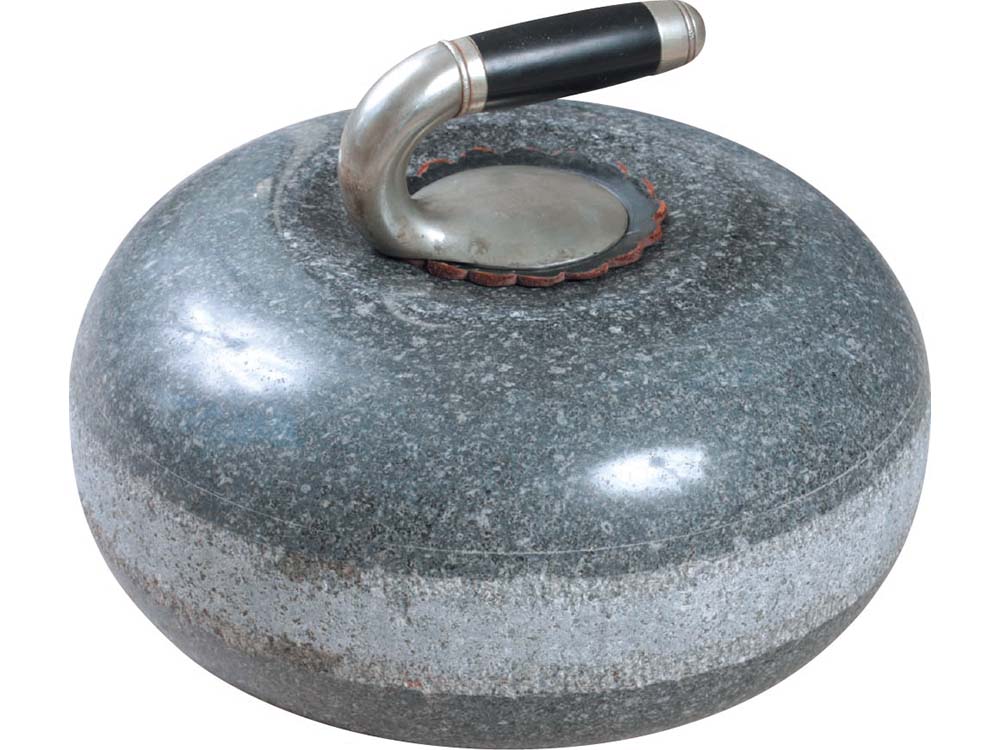

Curling Modification Example

1/1000mm wrap technology provides curling speed and fun curvature.

Before: Running edge worn and needs repair

Before: Running edge worn and needs repair

After: Running edge reshaped with micron accuracy

After: Running edge reshaped with micron accuracy

In addition to standard products, we accept custom orders for precision positioning units such as inspection plates and XY stages,

as well as repair, inspection and calibration of stone plates.

Please feel free to contact us first.